Injection Molding Process

Nanjing Emitech Mold Fabricate Process

Plastic injection molding is important in manufacturing. It has a number of benefits that can make mass production more efficient and consistent, like high efficiency, high consistency, low energy consumables, precision and complexity for example.

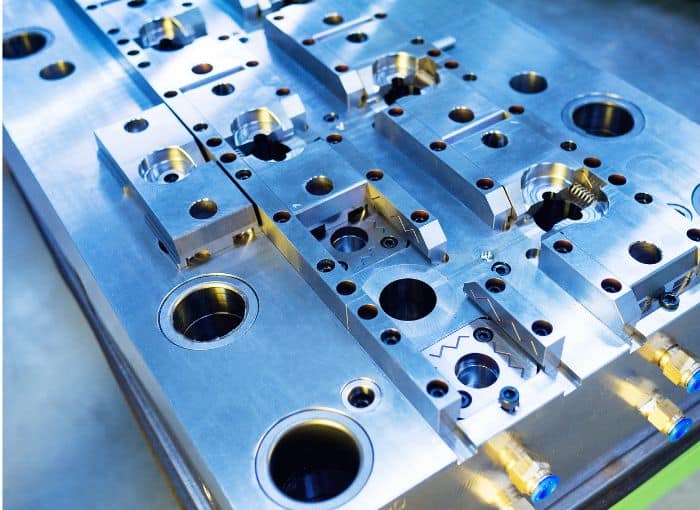

Injection Molds Design

Wall thickness: Surface shrinkage or air holes can cause uneven wall thickness, which can lead to defects.

Wall thickness: Surface shrinkage or air holes can cause uneven wall thickness, which can lead to defects. Material shrinkage ratio: The accuracy of injection molded parts is often lower than that of metal parts. The dimensional tolerances of mechanical parts cannot be applied for injection molded markets like plastic injection molding.

Material shrinkage ratio: The accuracy of injection molded parts is often lower than that of metal parts. The dimensional tolerances of mechanical parts cannot be applied for injection molded markets like plastic injection molding. Drafting angle degree: Allowing proper drafting angles can avoid product straining and top injury.

Drafting angle degree: Allowing proper drafting angles can avoid product straining and top injury. Injection parts distortion: Strive to improve the structure of injection molding products, avoid making a flat structure, set reasonable ribs and concave ribs, and minimize the application of reinforcement ribs.

Injection parts distortion: Strive to improve the structure of injection molding products, avoid making a flat structure, set reasonable ribs and concave ribs, and minimize the application of reinforcement ribs. Make sure the direction of the mold opening and the parting line are to reduce the effects of the mechanism on how it looks after use.

Make sure the direction of the mold opening and the parting line are to reduce the effects of the mechanism on how it looks after use.Injection Moulding

Mold steel materials preparation

Mold steel materials preparation Roughly processing

Roughly processing Precision processing

Precision processing EDM machining

EDM machining Mold parts CNC machining

Mold parts CNC machining Mold inspection

Mold inspection Mold assembly

Mold assembly Mold testing

Mold testing Plastic injection production

Plastic injection production

Roughly Machining

EDM Process

EDM is an affordable and durable process for making plastics. It’s quick cycle time, high tolerance, and low cost make it a popular option for manufacturing.

Molds Polishing

Polishing increases the beauty of the workpiece and makes it more resistant to wear. There are 6 types of polishing techniques, including mechanical polishing.

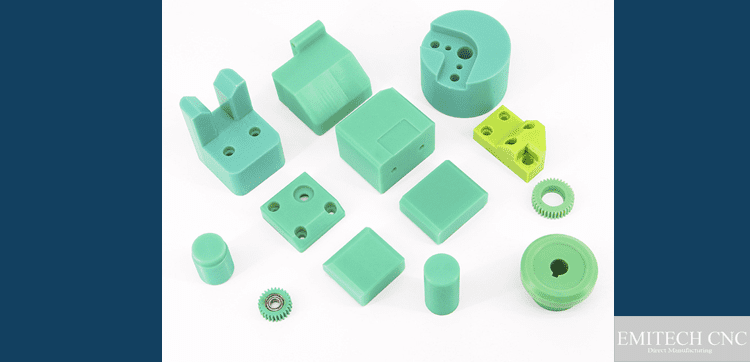

Projects

Nanjing Emitech offers plastic injection services. We’ve helped various industries with their molds over the years.

CNC Machining Parts

CNC Turning Parts

CNC Plastic Parts

Maintainance

What is a Plastic Injection Mold?

A Plastic Injection Mold is a machine that creates plastic parts from a design. It melts and forces the plastic into the mold where it is heated.

How to Maintain and Stock the Plastic Injection Mold?

If you are a plastic injection mold maker, it is important to clean your molds. It is important to clean them after each use and after making sure that they are completely dry. It is also important to dilute the cleaner before using it on the mold.

What Poisons are Common in Plastic Injection Molds?

One of the most common dangers in plastic injection molding is the release of poisonous gases. These can come from a variety of sources including cooling fluids, raw materials, or even the air. Inhaling these gases can be deadly, and they can also contaminate nearby areas with dangerous chemicals.